PVC waterstop

pvc water stop

The aim of installing waterstops is to block dilatation and construction joint of concrete and they are produced by extrusion method. This material is used to prevent the transfer of fluids through construction fittings. Most concrete structures under floors have conditions that lead to water penetration into the fittings and root gaps (connection fissures). Waterstops get installed in the root gaps and structures to prevent such leakage. The waterstops get installed in order to prevent the water penetration in the fissures of concrete structures such as: dams, tunnels, water treatment plants, underground structures, below-the-ground floors. Buildings, reservoirs and water channels, swimming pools, sewage treatment installations and offshore structures.

PVC concrete waterstops get installed between the two sides of the structure fittings aiming at caulking dilatation and construction joint; Hence, it creates a hard and impenetrable physical barrier. The width, size, and thickness of the waterstop are determined based on the type of structural fittings. This type of waterstop can be installed in any weather conditions and is very durable due to its constituent properties. Standard PVC waterstops of Setareh Mavadsara Company have high tensile strength, tear resistance, and longitudinal increase due to their special formulation and high-quality raw materials. PVC waterstops have high plasticity, which makes them usable in many moving joints. Other very important features of waterstops are the high impermeability of these materials and high resistance to acids, ozone, seawater and even diesel oil, alkalis, chlorinated water, and other water-soluble chemicals, and their color doesn’t change in the face of concrete, they do not react electrolytically with their adjacent metals, have a very high resistance to heat, are able to withstand hydrostatic pressures, and can withstand temperature changes.

Waterstop is produced in various widths, thicknesses, and sizes that are suitable for any type of construction. The durability and efficiency of the waterstop is directly related to the production quality of this product, which is measured and verified in laboratories according to the standard. This is a real challenge in the installation process. It is necessary to allocate enough time, accuracy in restraining the waterstops during concreting in order to place the waterstop correctly and to install it in the joints.

- Easy to install

- Secure and leak-free connection to each other

- High flexibility in length and width directions

- Performance equal to the concrete shelf life

- Resistant to alkaline reaction of concrete

- High tensile strength and longitudinal and transverse propagation

- Prevention of the water passage in expandable and construction joint

- Pools and tanks

- Dams and tunnels

- Water and wastewater treatment plants and other concrete structures

- Expandable and construction joint in prefabricated concrete structures

- Fixing the leakage of structures below groundwaters level (negative pressure)

- Fixing the leakage of buried and semi-buried structures

- Retaining walls and foundations

- Industrial concrete structures such as cooling towers and clarifiers

- Construction joint between metal parts and polyethylene exerted in concrete

- Roof slabs

- Hydraulic structures

- Interconnected concrete structures, waterstop is used in concrete joints parts of common dilatation and construction joints.

- Lengthy wall areas; where more than one step of molding is required for concreting

- Conditions that have stopped for some reasons due to concreting or the presence of many molds

- Where there is a need to change in the design form for design elements

- Prevention of sewage and water passage to other concrete structures

Dilatation and construction joints in prefabricated concrete structures, manholes and wastewater tanks

- Fixing the leakage of structures below groundwaters level

- Type: Soft PVC

- Color: Blue – yellow

Tensile strength: 18/2 N/mm2

- Percentage of longitudinal increase in the longitudinal direction: 420%

- Percentage of longitudinal increase in transverse direction: 390%

- Welding melting temperature: 240 °C

- Shore A: 75

Freezing point: -35 °C

Types of waterstops: PVC

Waterstops are grouped into three distinct categories:

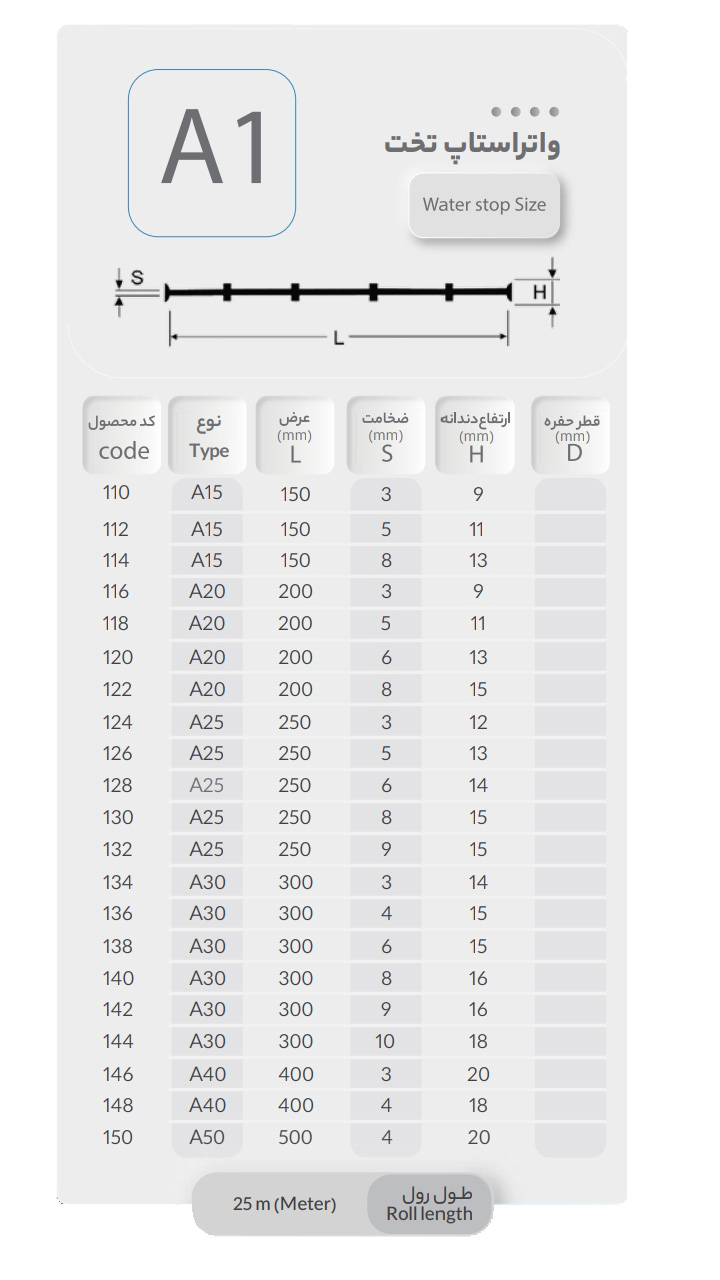

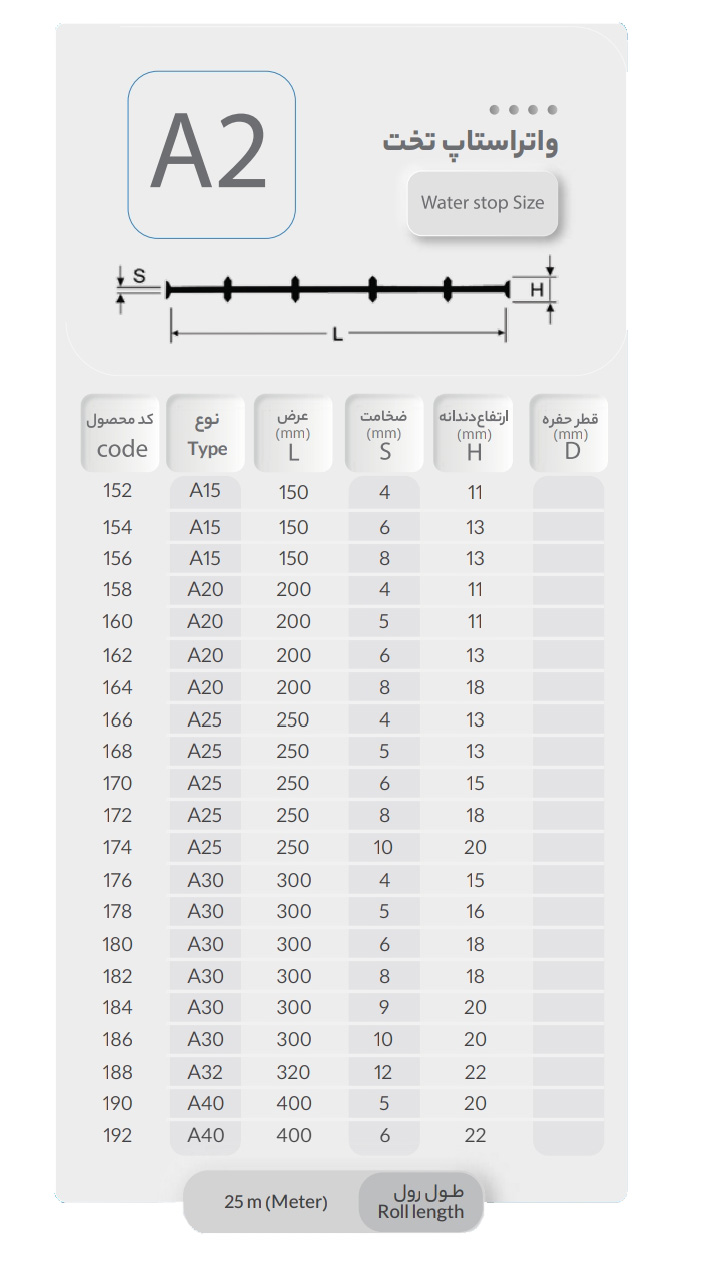

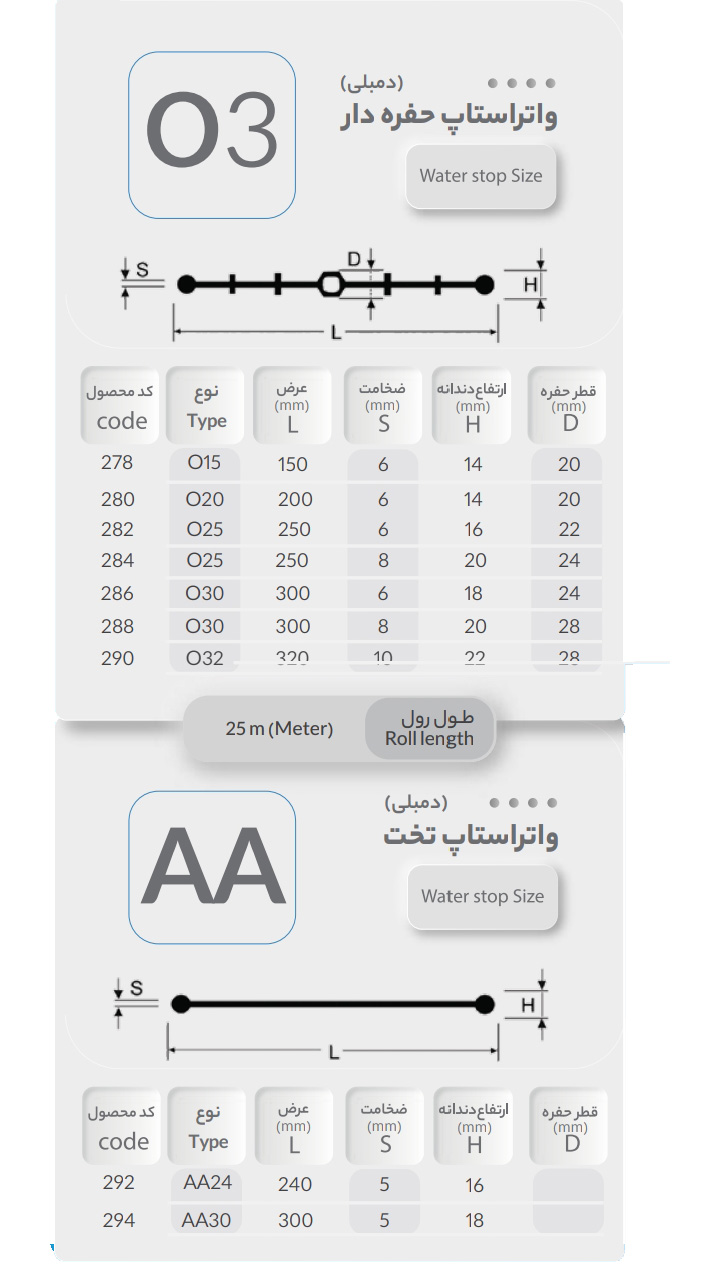

Flat-type waterstop:

Flat-type waterstop (A) is used for fittings without any movement of adjacent concrete parts called construction joint (fittings, fissures, and construction grooves).

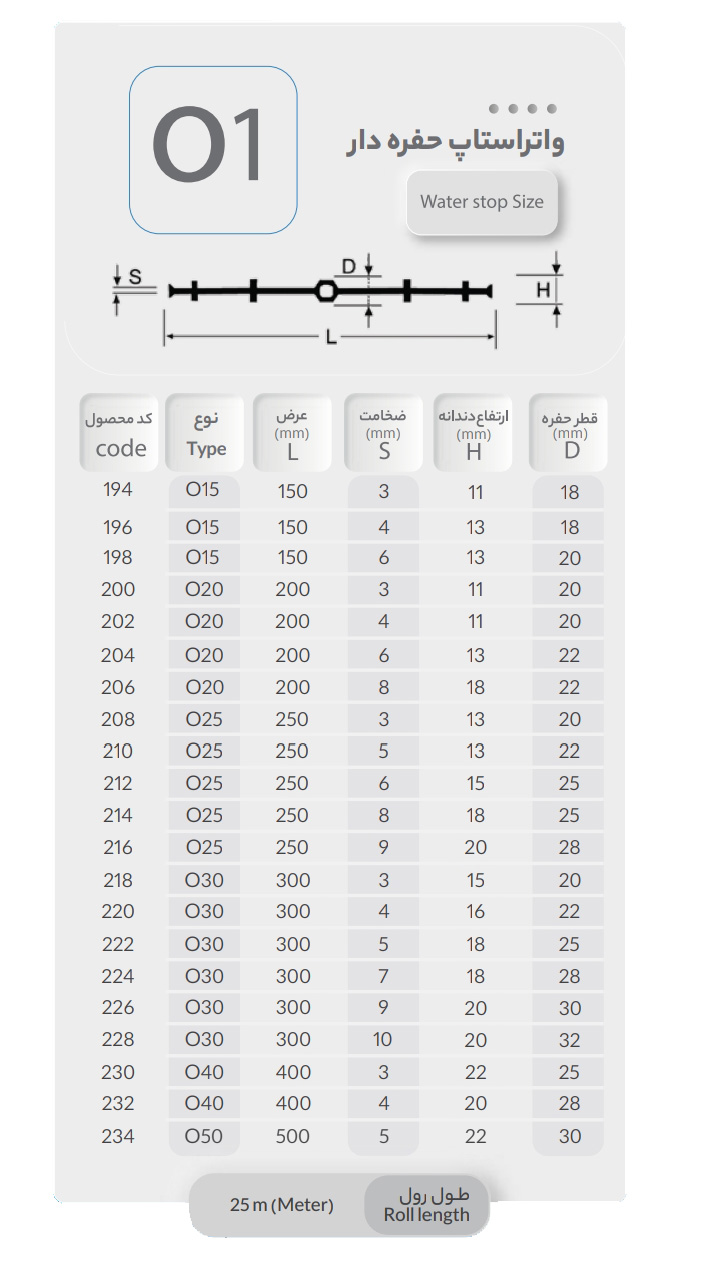

Perforated waterstop (O) is used for joints by moving adjacent concrete sections (dilation joint).

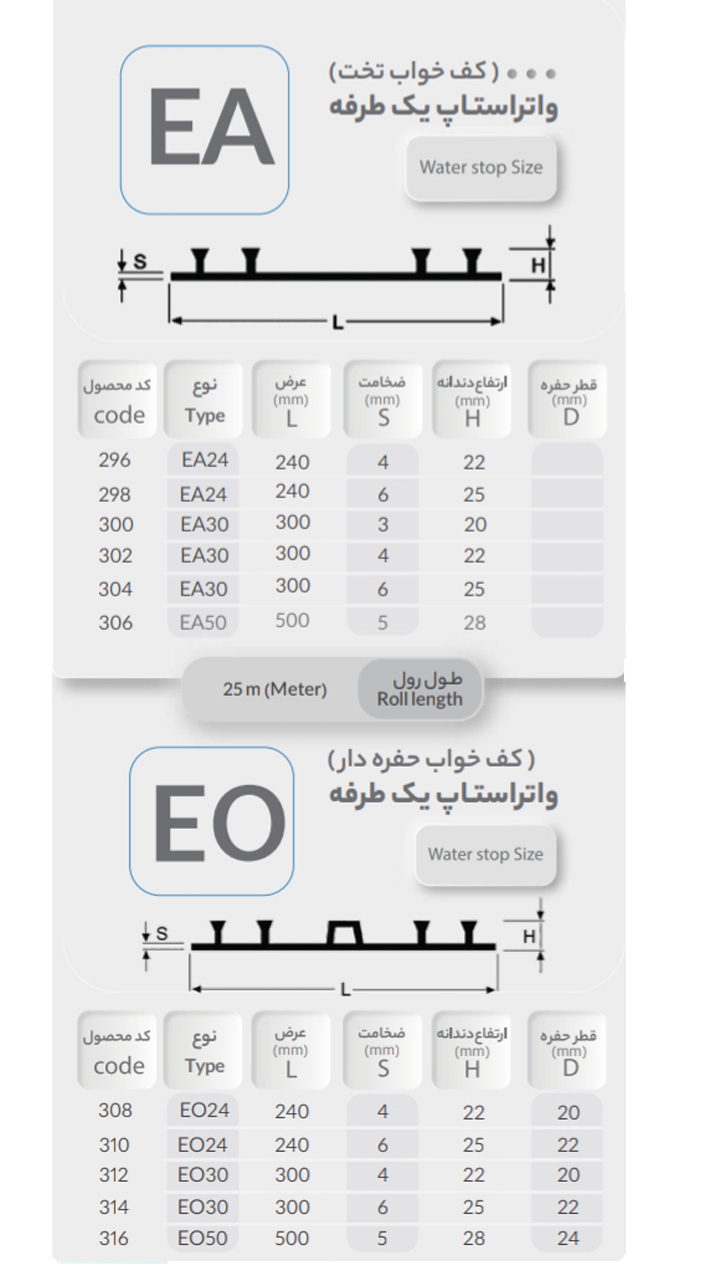

Waterstops, bedfloor

Other types of waterstops are bed floor (EO) and (EA), which are used for construction and dilation joints in the floor of concrete structures.

Due to the importance of using waterstops to calk concrete structures and tanks, which leads to the increase in the demand of contractors and employers, providing the highest quality and efficiency of the produced product is one of the most important goals of Setareh Mavadsara Company. In this regard, the company’s products are tested and approved in the most reputable and largest laboratories in the country, including “Oil Industry Research Institute and Razi Research Institute”, “Tehran Polytechnic University” and “Azmoon Foolad (steel test)”.

Waterstop is produced in various widths, thicknesses, and sizes that are suitable for any type of construction. The durability and efficiency of waterstop is directly related to the production quality of the product, which is measured and verified in laboratories according to the standard. This is a real challenge in the installation process. It is necessary to allocate enough time and accuracy in restraining the waterstops during the concreting in order to place the waterstop correctly and to install it in the joints.

Flat waterstop is used in concrete cutting sites; In this way, half of its width will be in the old concrete and the other half in the new concrete. Perforated waterstops in the embedded locations of construction joints and junes should be placed in such a way that the waterstop cavity be completely placed in the joint location after concreting the first and second sections so that the structure has the necessary pressure and tension resistance at the time of expansion and contraction.

Tip:

One of the most important uses of waterstop is to install waterstop on the rebar network. Unfortunately, the calking operation of the seams (fissures) has been completely or partially unsuccessful due to incorrect installation in many cases. Waterstop clamps are used to fix the waterstop in their places.

Waterstops welding and connection:

The best way to connect the waterstops to each other is to weld the waterstops by a special waterstop welding machine and it is not recommended to use other methods. Never pierce the waterstops, as this will cause the waterstops to rupture due to changes in stress.

PVC waterstop stabilization:

Waterstop stabilization operations are extremely important in its performance; PVC waterstop should be fixed symmetrically as to the seam (fissure) axis, so that it does not displace and does not change the position during the concreting. For this purpose, PVC waterstop is connected and fixed to surrounding reinforcements by wire and waterstop clamp. Complying with a proper distance is also required; The maximum distances of the PVC waterstop clamps are 25 cm.

Molds calking:

Molds calking is also important for installing waterstops; Make sure that the mold is completely calked in the PVC waterstop location when installing the PVC waterstop.

Concreting without creating a hole (cavity):

It is important to completely cover the waterstop by concrete and there should be no holes on the concrete in waterstop execution process. The PVC waterstop should be completely enclosed by the concrete and there should be no holes in the concrete. The height of concreting should be low and the concrete should have a proper flow and no separation.

Distance between PVC waterstop and vibrator:

It is necessary to observe the distance of the vibrator from the waterstop. The vibrator should never come in contact with PVC waterstop and its clamps. If you need to tap around external waterstops, care must be taken not to displace the waterstop when tapping the mold.

Here are some important tips to install the waterstop:

Waterstops should be installed in the center of the wall width. Waterstops should be installed in such a way that half of the width of the waterstop is installed in the primary concrete and the other half in the secondary one. In the case of perforated waterstops, care must be taken that the waterstop cavity is located in the center of the two concretes’ fissure. If the grid on the reinforcement in the foundation concrete does not allow the waterstop installation in the middle of the structure, then Ramka should be implemented. The waterstop inside the rebar network should be connected in such a way that it does not separate and displace in any way during concreting, staff traffic, and concrete pressure. Use the waterstop clamp to install the waterstop inside the rebar network, and if conditions don’t hold to install the clamp, then an auxiliary rod should be used to install the waterstop.

Waterstop connection and welding:

The connection of the two ends of the waterstop is mostly made in two-way, three-way, four- way as well as vertically and horizontally. The reliability for calking increases and welding the two ends of the waterstop will be performed correctly using the expressed methods.

The connection of the two ends of the waterstop is made in two ways:

- Cold connection

- Hot connection

Waterstop’s hot connection is made in two ways:

Butt welding: It is conducted by ax or sword soldering iron.

Welding: It is conducted by an industrial hair dryer.

Cold connection method:

The connection in this method is made using industrial PU glue.

• Shave the waterstop dentin by a cutter

• Impregnate the connection surface to the PU glue

• Place the connected surfaces on top of each other

• Press the two levels on each other for about 3 minutes

Waterstop fittings

1. Four-way fittings

2. Two-way fittings

3. Three-way fittings

4. + fittings

5. L connection

6. T connection

Some important recommendations and tips to maintain the waterstop are:

Place the waterstops on a pallet after emptying them from inside the truck.

If you do not use the the waterstop for a long time, be sure to protect the waterstop rolls by a suitable cover. Don’t open its rolls prematurely as much as possible before using the waterstop. The waterstop rolls should be protected from direct sunlight and placed in a closed container in hot weather conditions. The waterstop rolls should be stored in a chamber or closed container whose temperature is higher than the ambient temperature, in cold and frosty weather conditions.

If the waterstop is deformed due to prolonged transportation or over-stacking, then it is recommended to open the waterstop rolls before use and apply heat to achieve a smooth surface.

If the waterstops are torn due to traction or displacement, they will be out of order and if it is necessary to use it, then the rupture points must be repaired by the waterstop soldering iron. Do not pierce the waterstops to cross the wire. On concrete floors, care must be taken not to tilt the vertical waterstop treads exposed to concrete. Waterstops should be installed in such a way that a long period of time does not elapse from the moment of installation to the time of concreting; This is because the waterstop should not be exposed to direct sunlight or extreme cold. It should be protected by a suitable cover if necessary.

Packaging

Waterstops of Setareh Mavadsara Company are produced in 25-meter rolls. The project can be customized if needed.

Waterstops of Setareh Mavadsara Company are produced in 25-meter rolls. The project can be customized if needed.