Concrete spacer

We will introduce the concrete spacer and its properties in this section: they are plastic or concrete parts that are placed between the outer space of concrete and rebar and play a significant role in increasing the life of concrete structures by providing the creation of sufficient concrete cover.

Product code: PLASTIC SPACER CONCRETE

Products under the name of “Spacer” have been designed and produced that create a barrier against corrosive factors by being placed between the rebar and the external space of concrete. In fact, spacers are plastic or concrete pieces that are placed between the external space of concrete and rebar and play a significant role in increasing the life of concrete structures by providing the creation of a sufficient concrete cover. In other words, one of the most important factors to prevent corrosion is the concrete cover on the rebar.

In general, the spacer is used to distance between the rebar and the mold. The aim of installing the spacer in the space between the rebar and the reinforced concrete is to prevent the rebar corrosion. This piece prevents corrosive factors from reaching the reinforcement and causes an increase in the shelf life of concrete and rebar. Spacers are produced in different types according to the type and ingredients, which include plastic, metal, and concrete. One of the types of spacers can be used depending on the project and goals.

- Being cost-effective and affordable

- Need less manpower

- Light weight and easy portability

- Increase in execution speed

- Vertical surfaces such as walls, pillars, and circular sections of all types of prefabricated concretes

- Concrete slabs

- Structures and heavy floors such as: foundation, heavy beams, floors, beams, and shoring

- Light structures such as composite roofs

- Medium-weight structures, such as: beams, putters, and semi-heavy floors

- Specific gravity: 0.9 g/cm

- Minimum compressive strength: 20 N/mm2

- It can be supplied in bags of 500 to 2,000 pieces according to the spacer size

Classification of spacers

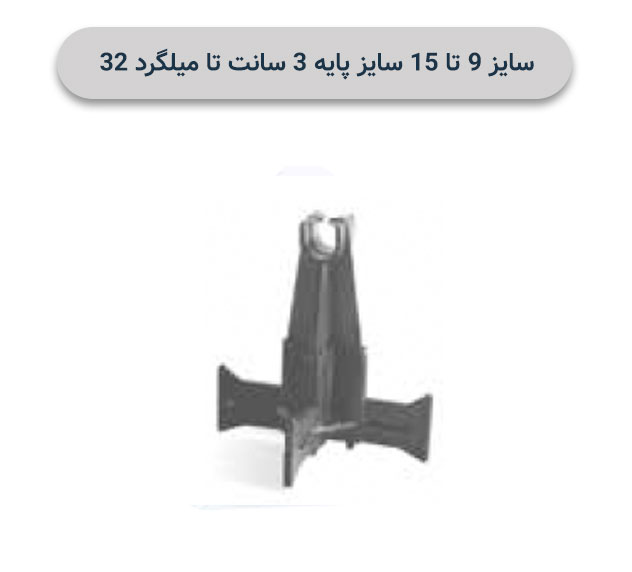

Spacers are produced and supplied with market in different forms based on the type of rebar support on the spacer and the rebar size. In general, all types of spacers can be divided into floor, wall, double-grid, and block beam spacers and we have an overview of the description and function of each one at below.

Floor spacers are used for foundations and heavy floors. The size of rebars, which can be used in this spacer, are between 8 to 32. Concrete floor spacers are produced in sizes of 15/12/10/9/7.5/6/5/4/3/2.5/2 cm and their main function is in beams with heavy grid, foundations, and floors.

This spacer is suitable to be used on walls. The use of this spacer in the walls is 3 pieces per square meter of the wall surface, and it is 16 pieces in pillars with a height of 3 meters and 24 pieces for the ones with a higher height in the pillar.

It is suitable for the parts that have dense and heavy rebar network and the rebar size is 8 to 32.

These spacers are used for vertical surfaces such as walls and pillars.

This type of spacer is used for heavy vertical projects, including in-situ piles and sliding molds.

Suitable for rebars with a thickness of 8-22 mm and heavy rebar network.

It is used to create two sizes of concrete cover in double-grid structures and slabs.

This spacer is used with medium weight and vertically. Another name of this type of space-creator is “Solar Spacer”.

It is used in light rebar networks, such as thermal rebars in roofs.

This spacer is specially designed for beams and causes a regular width distance in the lower longitudinal bars (in double type) and reinforcement (in triple type) while creating a cover in concrete.